Depth: how do enterprises deal with the supply chain in the "shock"?

The following article comes from source capital, and the author creates lasting real value

Source / source capital (ID: sourcecodecapital)

Share with Xu Bo

Supply chain is a management science in practice. For enterprise operation, the core of supply chain is "planning". "Plan" is the transmission of prediction and the feedback of prediction. If an enterprise's supply chain is not done well, it is essentially that the plan is not done well, resulting in the error being transmitted layer by layer.

I came from the manufacturing industry and have done Internet information service and third-party logistics. In recent years, I have been considering what problems the enterprise has encountered from the perspective of supply chain, how to form a problem system and how to establish a systematic solution from the perspective of supply chain.

It can be perceived that the supply chain will become more and more complex in the future. Entrepreneurs can establish the thinking mode of supply chain matrix and model. Using this thinking mode to look at the supply chain and the positioning of enterprises can gradually establish the core competitiveness of enterprises and improve their expansion ability.

01

Supply chain in "shock"

When we say "shock" in the supply chain, we should talk about two levels of shock, enterprise level and social level. In the past, the supply chain of an enterprise was a constant like sales and marketing; But now it has slowly changed from a constant to a variable, so it is difficult to predict which direction to oscillate next.

At the enterprise level, the change is caused by the current complex international situation, global epidemic, demand for capacity optimization, competitive risk, credit endorsement and other comprehensive factors. From the financial point of view, the explicit costs of procurement, transaction, internal, quality and so on have increased in an all-round way; The hidden costs such as after-sales, also known as "the cost under the iceberg", have also increased in an all-round way. From the perspective of operation, there are huge problems in the continuity and stability of enterprise operation. From the perspective of compliance, the delivery between countries and enterprises fluctuates. These operating conditions pose challenges to the supply chain. When expectations and plans become more and more difficult, we need to find the underlying logic and solution to make expectations and corresponding plans.

At the social level, the supply chain changes from continuous to "intermittent". In recent years, we have found that the supply chain has become intermittent, not broken, but "intermittent". Since May 2020, the ports in the United States have had problems, and the development peaked from July to October last year. China's upstream supply chain is not broken, but the goods are broken when they are transported to American ports by sea and air. The "discontinuity" brought by the epidemic this year is in the upstream of the supply chain, which is mainly reflected in the upstream of the "business flow", that is, there are problems in the upstream shipment of manufacturing end and logistics. It can be seen that a large number of industries and enterprises will adjust the supply chain next. With the superposition of various variables, the supply chain has entered a turbulent period from a stable period.

The specific problems encountered by each enterprise are different, but I think that how to think about the supply chain from the bottom, master the logic of the supply chain and grasp the problem-solving ideas can bring the problem-solving perspective to entrepreneurs and find appropriate solutions. In the future, as the supply chain becomes more and more complex, we need to let enterprises form supply chain capabilities through deep binding and integration, so that the supply chain can help enterprises succeed rather than become a "hind leg".

02

Through the supply chain, find the enterprise positioning and competitiveness

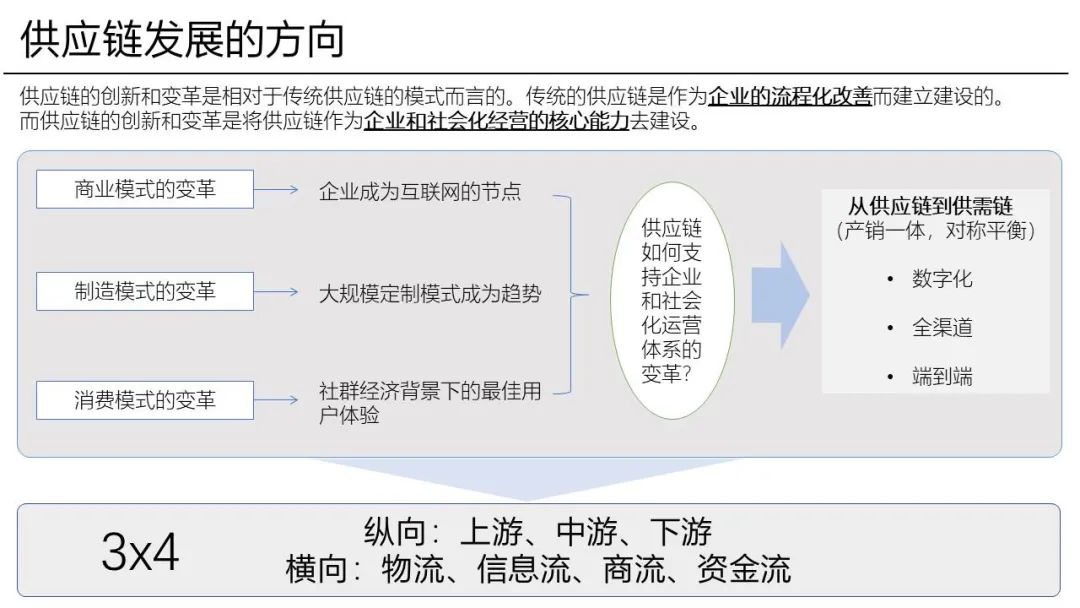

The development of supply chain is a general trend. In 2017, the supply chain was included in the GDP account and became an important guiding force for China's transformation from high-speed extensive development to high-quality intensive development. At the same time, the business model, consumption model and manufacturing model are also changing with the development of society. The Internet of things, the Internet, artificial intelligence, big data, 5g and carbon neutralization have all become the elements to promote the innovation, transformation and development of the supply chain. From the macro level, to analyze the impact of these changes, we need to find the power to support the development of enterprises. From the perspective of supply chain, this power is "three tours" X "four flows", that is, the 3x4 model of supply chain. The traditional supply chain should include three levels: procurement, production and delivery. In a broad sense, it should be a combination of logistics, business flow, capital flow and information flow, which serve enterprises from different angles; And the different positions of enterprises in the industry, namely upstream, midstream and downstream. If you build this 3x4 model in your mind and bring your own enterprise into it, you may be able to find the current positioning. This is the starting point of analyzing the logic of supply chain. At the same time, it can also be extended to how to treat the core competence and development logic of enterprises, and it is also the secondary development of enterprise resources.

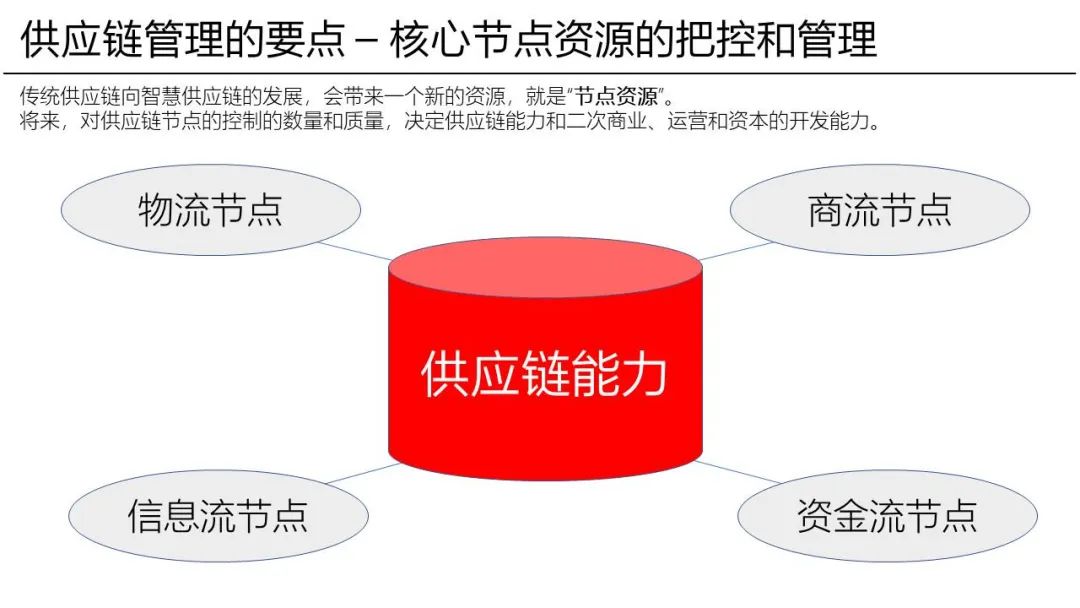

From the micro level, the pure supply chain is the enterprise's procurement, production and delivery process. Services for this process should be planned, that is, SIOP (sales, inventory & Operations Planning). There are many supply chain management and optimization tools and supply chain management systems in the market. For example, JD and Alibaba have their own supply chain systems. With the increasing scope of management, including the management of raw material suppliers and logistics raw material suppliers, radiating to the management of enterprise funds and personnel, some core nodes of supply chain management have gradually formed.

It can be seen from the 3x4 model that there are many cross converging nodes in different logistics, business flow, information flow and capital flow. No matter which enterprise, in any module, it is impossible to include all the nodes controlling the supply chain. The core ability of an enterprise is the ability to control its core supply chain nodes, which determines the basis for the survival of the enterprise in this industry. Moreover, with this foundation, we can see the space for the future expansion of enterprises and the space for the radiation of core capabilities, which is a basic logic based on the development of supply chain.

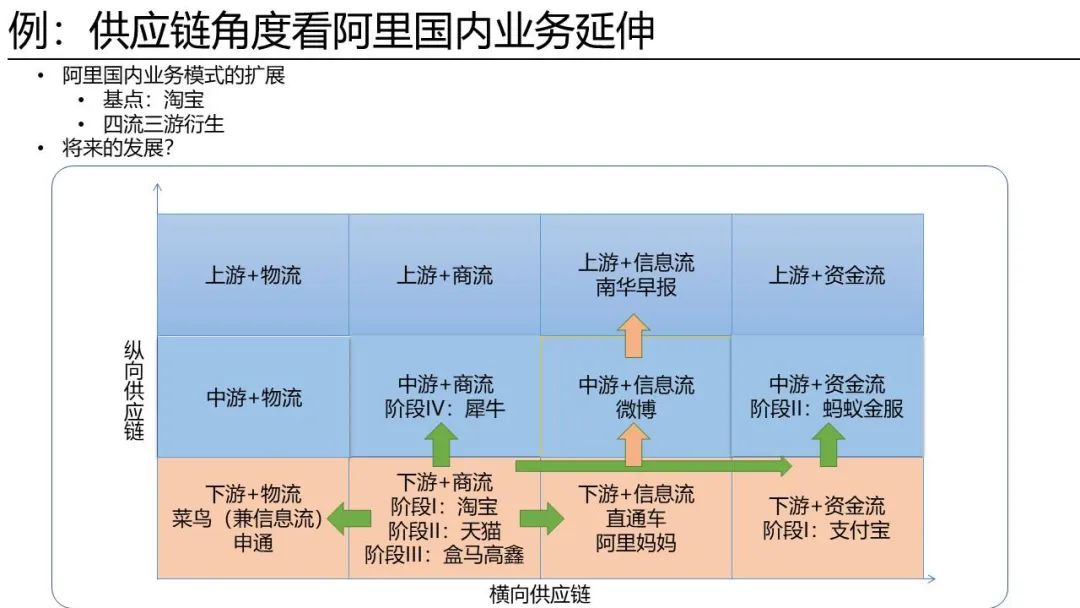

Taking Alibaba's domestic business as an example, you can see the specific application of 3x4 model. Alibaba's domestic business has developed from Taobao to tmall, and tmall has developed to the new retail of HEMA and the acquisition of Gaoxin. This is the stage of business flow development. In the process of business flow development, Taobao tmall has brought a lot of express demand, so it has established rookie logistics. Rookie logistics is not only a logistics platform, but also an information flow platform. Moreover, Alibaba has continuously extended the warehouse distribution system from holding to wholly-owned Shentong. As the core, business flow extends to logistics and information flow. Information flow business also includes through train and Ali mother, which account for a very high proportion of total revenue.

Through the business flow in the supply chain, the most value-added information flow services are extended, and the information flow extends upstream. Because there is a business flow that drives the capital flow, Alipay has become a credit bridge between buyers and sellers. In this process, we found that the business flow extends upward to the recent rhinoceros intelligent manufacturing, which is the business flow extends to the manufacturing end and then to the purchasing end.

From the perspective of supply chain, Alibaba's development, that is, from the perspective of business flow as a core, after bringing a large amount of flow, it will be realized not only in business flow, but also in logistics, information flow and capital flow, and gradually expand its territory. This is analyzed from the perspective of supply chain. The basic point is Taobao, which is Alibaba's domestic business.

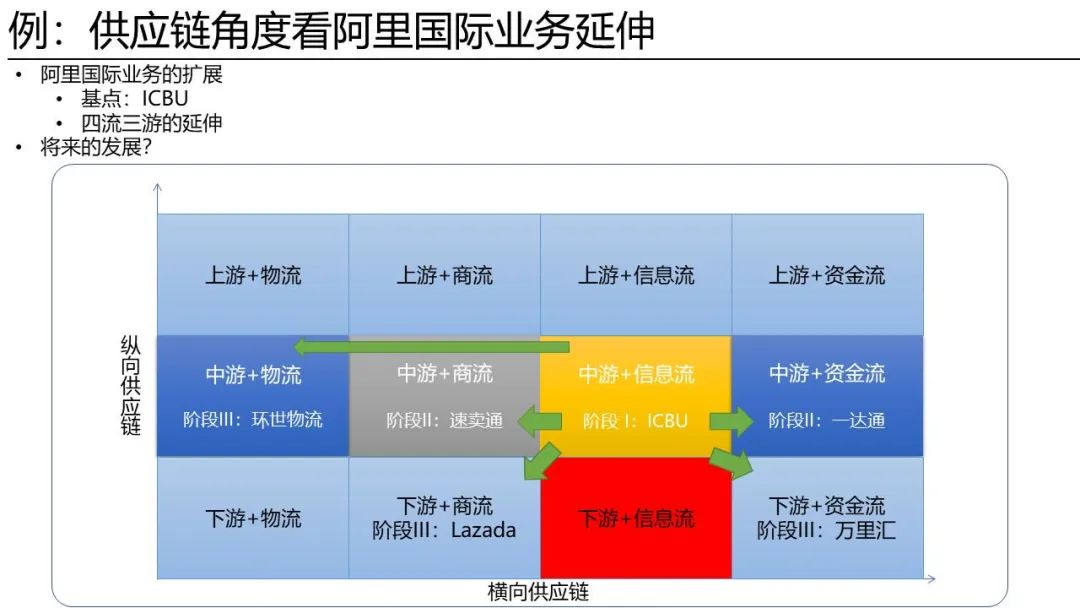

Similarly, look at Ali's international business. Alibaba international business was first established as Alibaba international station, which does not generate transactions. It is an upstream and downstream matchmaking business of information flow. Taobao is a trading platform, but because information flow brings a large number of upstream and downstream agglomeration, it can do business flow. Therefore, Alibaba made express. Express is now a small wholesale platform, but it is almost the largest local e-commerce platform in Russia and South America.

After the quick sale link, it was found that domestic and foreign transactions brought logistics demand. It was difficult for the international logistics side to form a logistics system through mergers and acquisitions or shares in four links and one access like domestic business. Therefore, it began with customs declaration, integrated customs declaration through one access, and then integrated its trade into one access. Later, one access had many problems, such as credit problems, tax rebate problems, etc.

However, the huge flow agglomeration and logistics agglomeration brought by yidatong make it have huge space in the whole international logistics end. Therefore, they acquired Huanshi logistics two years ago, which can be compared with Maersk's acquisition of Li & Fung logistics. Maersk extends from trunk logistics to onshore logistics, and Ali extends from international trade platform to international logistics. Through the information flow, they found that there was also the demand for capital flow. The cost of small and medium-sized payment through the bank was very high and inconvenient, so they established wanlihui and formed a capital flow channel. This is the business of Alibaba international. We can see how to extend horizontally and vertically from the perspective of supply chain. With such logic, we can also analyze many enterprises to see how they move from business flow to logistics and from logistics to capital flow.

03

Supply chain management, changing variables into constants

Supply chain thinking is applied to enterprise top-level design, including business opportunities, business models and strategic planning. The application of supply chain thinking to the practical operation level of enterprises is procurement, production and delivery. In other words, the lowest cost brings the highest delivery satisfaction rate to the enterprise. The delivery satisfaction rate is composed of different costs, including low cost and high cost.

However, since the supply chain is no longer a constant, but a variable, there is a huge gap between the ideal model and the complex situation faced by the actual situation. Therefore, turning the variable into a constant and shortening the distance between the ideal model and the reality has become the core competence and the highest value of the supply chain. If this value is realized in the enterprise, the enterprise will have the core competence. In short, the core of the supply chain is planning. Planning is the transmission of prediction and the feedback of prediction. It is the core of the core of the supply chain.

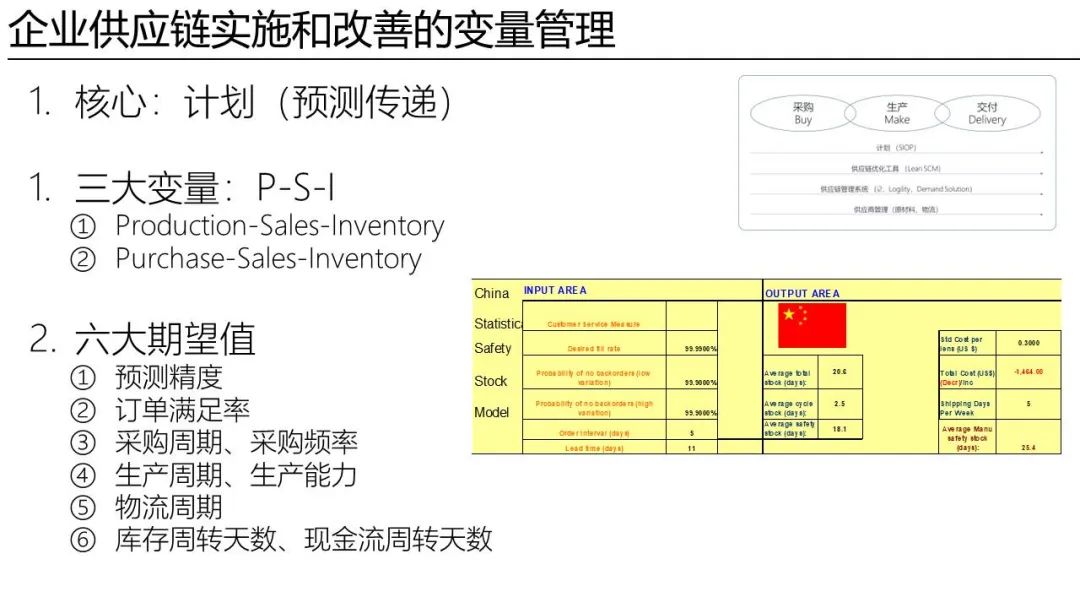

There are three variables p-s-i. for manufacturing enterprises, P is production, s is sales and I is inventory. For trading enterprises, P is purchase, s is sales and I is inventory, so p-s-i is the three variables of the supply chain.

There are three variables p-s-i. for manufacturing enterprises, P is production, s is sales and I is inventory. For trading enterprises, P is purchase, s is sales and I is inventory, so p-s-i is the three variables of the supply chain.

The three variables are generated by what kind of secondary variables, that is, the six expected values. Forecast accuracy, order fulfillment rate, purchase cycle, purchase frequency, production cycle, production capacity, logistics cycle, inventory turnover days, cash flow turnover days. In summary, there are 12 variables that bring six big expectations. For example, the prediction accuracy should be 99% and 70%, which will bring different losses to the supply chain. For example, in the aspect of order fulfillment rate, 99% and 80% of orders should be met. Although the cost of achieving 99% is very high, if it is 80%, the cost of the supply chain may not be high, but the customer experience is poor.

The combination of procurement cycle and procurement frequency is the control ability of procurement and brings the advantage of procurement cost. Production cycle and production capacity. Production has now become the capacity of the supply chain. In the past, it was independent of the supply chain. Your high production capacity, good production equipment, good proficiency of member workers, short shift time between different products, and 8-hour, 16-hour and 24-hour continuous rotation of production capacity bring great advantages to the supply chain. The logistics cycle is short, which means that your inventory turnover rate will increase. If the logistics cost rises, it is necessary to balance the proportion of inventory cost and capital cost, which is where technical optimization can be done in the supply chain.

Finally, the turnover days of inventory and cash flow are the cost under the iceberg, which can't be seen by others. Reducing the days of inventory turnover will be of great use to the enterprise's cash flow and capital cost. Cash flow is the same. If it turns around six times a year and once every two months, one hundred million can generate sales of six hundred million. Simply from the perspective of goods turnover, regardless of other costs, if your turnover rate is 12 times, 100 million can generate 1.2 billion sales, if it is 24 times, 100 million can generate 2.4 billion sales, which is the huge support for capital cost and great impact on enterprises brought by the supply chain. From the perspective of R & D and supply chain, it can provide information for enterprises, which is the same as that of R & D and management enterprises.

04

Credit and contract, new supply chain partners

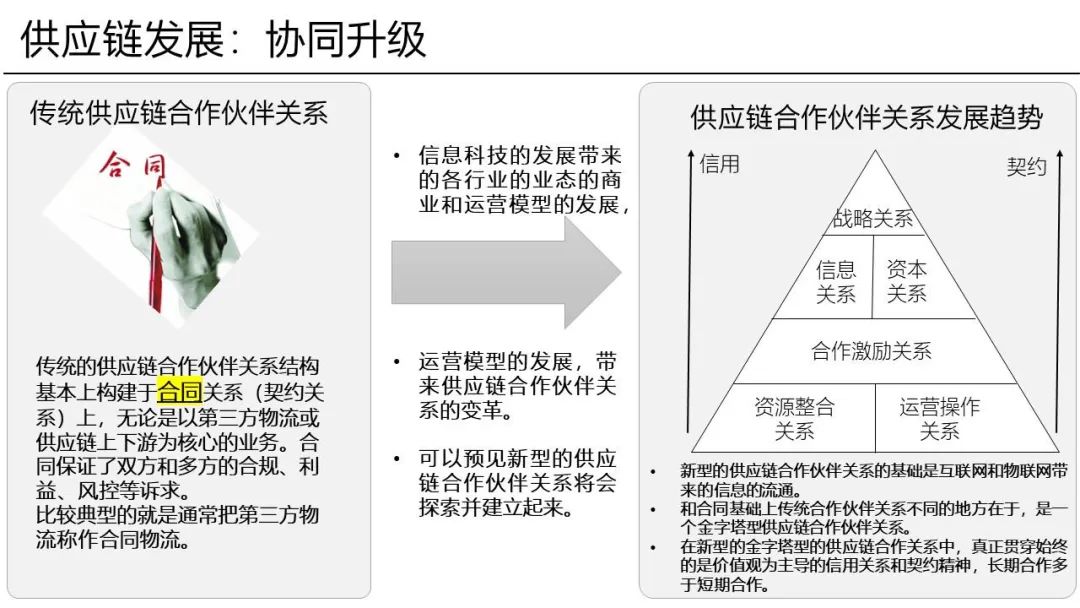

Supply chain is a collaborative relationship. With the development of science and technology and the change of operation mode, it can be predicted that many enterprises may be developing the supply chain relationship into two dimensions: credit and contractual relationship, not just contractual relationship.

If you are a fast-growing enterprise and have a lot of capital support, and you are optimistic about this track, whether it is called "savage growth" or "high-speed growth", you can't build the supply chain capacity purely from the contractual relationship. You must build the credit relationship. The two dimensions of contract and credit form the upstream capacity or service capacity of the supply chain. Service capability refers to the supply chain system supported by external logistics services and upstream procurement services. The system is a pyramid, which has cooperation in strategic relations and capital.

If you have capital capability, you can control the raw materials of the core purchased spare parts into the capital relationship. If there is no such production and research and parts production capacity, control the capacity through the supply chain and form the upstream and downstream connection relationship with a capital relationship and information service relationship. The supply chain does well, provides various cooperation incentives and so on, and then enters the linkage relationship between resource integration and operation.

In the future, the supply chain will become more and more complex. The efficiency cost of the supply chain is a dynamic analysis method, including a variety of complex analysis. In the past, there was a special FP & a department (Finance Planning and analysis) in the financial department of multinational enterprises. Now I will also allocate such a position in the financial department, in order to convert the efficiency cost of the whole supply chain into financial analysis. Both explicit and implicit costs should be clear at a glance.

With the development of the supply chain, the developing supply chain relationship can already contain more than 70 variables. Before, Alibaba has made a model, which probably uses more than 70 variables to make intelligent algorithms, including inventory, production and procurement. In fact, more than 70 variables are simplified into 12 variables, and then simplified into 6 core variables. They are continuously fed to the system for practice through big data, and finally form an intelligent algorithm for the supply chain.

No matter how complex changes the supply chain will face in the future, for enterprises, the essence is how to form the enterprise's supply chain capability through deep binding and integration, and then extend this capability to the business model, from business flow to information flow and capital flow. If the enterprise does not realize these, it shows that the supply chain has not been fully developed and is dragging its feet. In the digital and intelligent era, when the supply chain becomes the core competence of enterprises similar to sales, finance, marketing and so on, enterprises will move from start-up to maturity, bringing the improvement of the whole terminal capability and service capability, which is also the general trend of supply chain development.

In the future, we can see that the supply chain will change from constant to variable. What the supply chain does is to change the variable into constant again; Second, the supply chain will move from the background to the foreground of enterprise management; Third, from flexibility to "flexibility + toughness", the "flexibility + toughness" of the supply chain is more needed in the period of shock. The resilience ability is the ability to be strengthened than the flexibility ability, and the resilience is realized through strategic cooperation, capital cooperation and the supply chain itself.

Xu Bo has successively worked in multinational enterprises such as general electric, Johnson & Johnson and Honeywell. He is responsible for supply chain management in Greater China and the Asia Pacific region. He has made breakthroughs in multinational companies' supply chain strategic layout, business development, product strategy, process reengineering and team formation in China and the Asia Pacific region. He was responsible for establishing the strategy and Investment Department of DHL supply chain business, and led the strategic planning and M & A and investment promotion; He also served as general manager of modern logistics of Bailian Group. Xu Bo served as senior vice president of focus technology and former executive president of focus technology in the United States.

Source / source capital (ID: sourcecodecapital)

Share with Xu Bo